Conditions of Use

Crabwood Foam boards are intended for normal conditions of dry internal use. All performance testing of CrabWood Foam boards has been carried out using dry ex-factory product. CrabWood Foam boards can be exposed to moisture or be installed in situations where extended exposures to humidity’s of 95% . The existing suitable surface finish can withstand wet areas where liquid water or high humidity can be expected. Acrylic emulsion, gloss and semi-gloss alkyd paints are suitable coating systems if desired. It would be preferred that Bathrooms, kitchens and laundries have adequate ventilation or heating to avoid condensation build up.

CrabWood Foam wall boards is a finishing material and must be fully protected on construction sites and during construction from direct or indirect damage, excessive sunlight or moisture.

Planning and Measuring

• Good planning of sheet layout is important.

This will reduce wastage and keep the number of joints to a minimum, saving

time and extra costs.

• On ceilings

the use of maximum sheet sizes minimises the occurrence of end butt joints.

Where end butt joints occur they must be formed, preferably, on framing members

where joints can be neatly finished.

• Sheets may be fixed either vertically or

horizontally and should ideally run right through and over electrical sockets

and ceiling light openings. The openings can then be cut out when sheets are in

place.

• The CrabWood foam sheets can be fitted near flush to door or window frame corners or on jamb studs but an 8-10 mm gap should be maintained to allow for timber frame movements as this is a point of stress.

Delivery, Handling & Storage

• Where possible CrabWood Foam Boards should

be delivered to site immediately or only a few days before installation as this

greatly reduces the possibility of damage.

• Sheets should be neatly stacked on their horizontal edge to avoid sheet distortion, damage. This can be achieved by stacking on a clean flat surface a minimum of 100 mm above ground level that is not susceptible to moisture. Do not stack directly on concrete floors

• Care should

be taken to prevent any undue sagging or damage to edges, ends or surfaces

during storage and handling.

• All materials should be kept dry, preferably

by being indoors above floor level and under cover (especially when storage is

likely to be for a lengthy period). While stored, foam boards should be

protected from moisture ( cover with plastic sheet or tarpaulin )

• CrabWood Foam Boards can be used on areas

exposed to moisture.

• It is preferred that either face of the sheets

not be placed in a horizontal position to prevent footprints and other marks or

damage to the face.

• Cracked or damaged sheets must not be used.

• Floor Loadings should be considered as

Meltin Vaste Foam boards can weigh in the range of 700–900 kg/m3.

Pre-Inspection of the Site Framework

• Check that the framing is plumb, level and

square and has been erected according to the relevant building specification.

The framing must have a minimum flat face width of 35mm for timber and 32mm for

steel.

• Plumbing and electrical services should be

installed before CrabWood Foam Board is fixed and all service ducting, pipes,

outlets and electrical connections should be set back from the framing and not

protrude beyond the face of the framing.

• Make sure

all contact surfaces of the framing are dry and free from dirt, grease, oil or

any other foreign material.

Note – The

fixing of CrabWood Foam boards is deemed to be an acceptance of the substrate,

so it is important to make sure that the above requirements are adhered to.

Framing

Spacing. The spacing of framing

support for CrabWood Foam Board shall not be greater than 600 mm centres for

all thicknesses of CrabWood Foam boards. The requirements for framing spacing

are detailed below.

• It is recommended that Framing centres be

kept at 450mm in Bathrooms or other areas that may be subject to moisture and

steam when using 10 mm CrabWood Foam

Board for ceilings. On ceilings we recommend the use of steel battens, as

timber battens can be subject to expansion and contraction.

Surface Joints and angled joints

A Versatile Medium Weight Filler

We would recommend ADOS Plastic putty to fill all all joints, scratches / screw holes and accidental dents using a spatula or scraper to achieve a smooth finish. Once you have filled the gaps embed the fibre tape and apply one more surface coat and allow to dry. Depending on the temperature and the humidity drying time can vary from 30 min to an hour . Once the surface is dry you can sand the surface smooth . Wipe the sanded surface with a dry cloth to remove all loose dust before you start painting. . The finish should be free of tool marks and ridges.

ADOS Plastic Putty is an all-purpose, versatile,

fast curing, medium weight polyester filler. It gives an extremely high quality

finish for general body filling on a variety of surfaces.

Please ensure

you apply the filler in 2-3 coats to ensure proper drying between coats.

Uses

Jointing tape

FibaFuse® is an innovative paperless

drywall joint tape designed for professional renovators and re modellers.

FibaFuse is a mold-resistant glass mat drywall tape that is ideal for use with

mold-resistant and paperless drywall systems for high-humidity and

moisture-prone applications.

Fiba Fuse is easy to cut and retains its folds, making it easy to install by hand on joints in corners.

GENERAL CEILING INSTALLATION

The following

section covers the installation of CrabWood Foam Boards in ceiling

applications.

Inspection of the Framing

• Flatness of Framing :

Inspect the

surface of the framing and ensure that it is flat. In particular take note of

nails not protruding over the surface, nogs not flush, hold down straps not

checked in flush to the surface etc.

• It is

important to ensure the framing is dry before fixing ceiling linings.

Cutting

CrabWood Foam Board

• CrabWood

Foam wall board is easily cut using conventional tools ( Saw ) or power tools.

• Cut-outs

for lighting fixtures and other penetrations should be marked before cutting commences.

CEILING INSTALLATION

Fixing to Ceilings using Adhesive/Screw

• Fix ceiling

sheets across battens or joists.

• Steel

battens are recommended.

• We

recommend 10mm sheets suitable for ceilings.

• Apply

adhesive to battens or joists at 200mm centres between centre and edge of

sheet.

• Start

fixing from the centre of each sheet outwards.

• Position the sheet hard up to the framing,

single screw at the centre line and the edges across each batten.

• Nailing is

not recommended.

• Single screws to be minimum 12mm from sheet edge. • Press the foam board where adhesive has been applied to ensure full contact.

• Sheet end

joints can be made on framing. If not ensure they are in level with each other.

• Adhesive

can be applied to the sheet edges or under screws.

• All joints

between sheets should be filled with ADOS plastic putty and allowed to dry.

• Use long

length sheets to minimise sheet end butt joints.

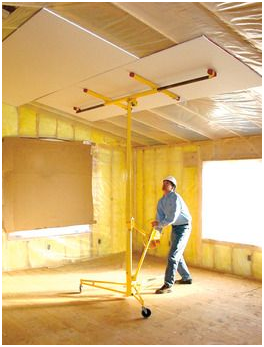

• The use of a drywall lifter will greatly

assist the builder in achieving optimum results.